Innovative Spaces

April 16, 2024

Drone Facility Opens

The University of North Texas officially opened the UNT Advanced Air Mobility testing facility this spring at Discovery Park, the largest research park in the North Texas region.

With a sprawling 36,000 square feet, the drone facility is the largest of its kind in Texas and one of the biggest nationally.

The facility stands 85 feet tall, 120 feet long and 300 feet wide allowing for the flight of multiple unmanned aerial vehicles or UAVs while in compliance with Federal Aviation Administration (FAA) regulations.

Drone facility researchers can analyze UAV technology, examining how specific maneuvers impact performance, exploring safety measures like collision avoidance and testing communication between UAVs and stationary receivers on the ground or autonomous ground vehicles. Given the facility’s large size, researchers can test signal strength from multiple angles, heights and distances.

“Drones and UAVs will be key in moving people and cargo much faster in our future. This facility gives our UNT experts, external research collaborators and industry partners the opportunity to shape the advancements of air mobility technology,” says electrical engineering professor Kamesh Namuduri, who is part of the Advanced Air Mobility National Campaign Project, which unites entities including Bell Textron, Unmanned Experts, AAMTEX, Avianco, Metron, Hermes Autonomous Air Mobility Systems, Hillwood and others.

Construction of the netted drone facility began in 2022 under the guidance of faculty affiliated with UNT’s Center for Integrated Intelligent Mobility Systems (CIIMS), an interdisciplinary endeavor paving the way for the future of transportation and mobility by creating solutions for the complexities of devices such as UAVs and autonomous cars from the programming needed to operate them to policies guiding their successful integration into everyday society.

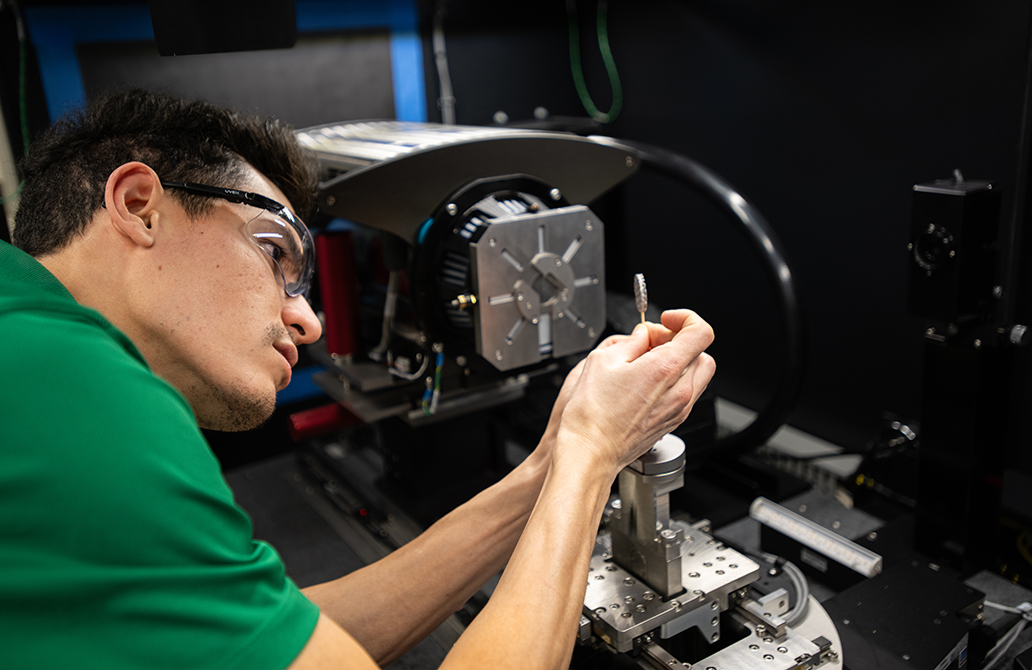

Adaptive Additive Manufacturing

UNT’s Center for Agile and Adaptive Additive Manufacturing (CAAAM) added several new machines in 2023 to expand its research capabilities and better serve as a testing ground for innovative materials research. An ultrasonic atomizer helps produce metal powders, the most important component in additive manufacturing. Other machines include a variable temperature micro-indenter, which can measure properties like hardness and elasticity, and a high-speed spectrograph for gathering data about molecules in materials.

Greenhouse Facilities

The UNT Greenhouse Research Facilities include three greenhouse complexes — two on the main campus and one at UNT’s Discovery Park, which enable research of myriad plants. The Discovery Park Greenhouse Complex has more than 4,000 square feet of climate-controlled greenhouse space. Each of the four cells in the complex are equipped with supplemental high-intensity discharge lighting, shade curtains, automatic irrigation to assist in meeting the desired growth needs and new evaporative cooling systems.

High Performance Computing

UNT’s Department of Chemistry offers computational facilities for running simulations to assist in solving complex chemical problems. For research, there are high performance computing (HPC) facilities providing 160 HPC servers with a total of 4,314 central processing unit cores, 106 graphics processing units, 34 terabytes of memory and 1.73 petabytes of disk space. There also is a wide selection of computational chemistry software available. Resources for both undergraduate and graduate education include 28 All-In-One Dell OptiPlex 7460 personal computers equipped with ample processing and memory.