It is a time of marvels and miracles, a time when 3D objects can literally be printed from a computer. It’s the Fourth Industrial Revolution, when manufacturing design, process and production are combining into one comprehensive whole.

New technology is leading industry into the age of additive manufacturing where it will be possible to design and print a final product using only the materials needed — without ever leaving your chair.

“The uses for additive manufacturing have the potential to transform a wide variety of industries — from the oil fields to the operating rooms,” says Narendra Dahotre, interim vice president for research and innovation and University Distinguished Research Professor at UNT. “Imagine knowing exactly what you want to create, exactly how much it will cost, exactly how much materials will be needed and exactly how long it will take to complete. Additive manufacturing is the industry’s dream come true.”

UNT’S ADDITIVE MANUFACTURING LAB

UNT researchers’ goal of transforming manufacturing technologies to better develop complex 3D objects to create viable market-based solutions that impact almost every industry — all while producing practically zero waste and cost savings that give Texas’ companies an advantage — is closer to reality thanks to $10 million in funding awarded by the recently convened 86th Texas Legislature.

The funding is for UNT’s Additive Manufacturing Laboratory (AML) that was officially opened in November 2018 at UNT’s Discovery Park — the North Texas region’s largest research park — and now will be transitioned into the Center for Agile and Adaptive Additive Manufacturing.

“We are grateful to the Legislature for funding our new center and especially appreciative of the unwavering support we received from Texas Senator Pat Fallon and Representative Lynn Stucky,” UNT President Neal Smatresk says. “Through CAAAM, UNT will advance its research and expand its role as a leader in this exciting new technology.”

Leading the Way

With world-renowned faculty expertise in the emerging field, UNT launched the center under the umbrella of the university’s existing Materials Research Facility, which is co-sponsored by the Office of Research and Innovation and the College of Engineering for the dual purpose of research and providing students with additional hands-on educational opportunities in this growing area.

UNT has developed one of the most advanced university research facilities in the nation for materials analysis, allowing faculty and industry to collaborate to advance the science and application of materials processing and additive manufacturing. Ultimately, UNT intends to establish a Texas-based prototype center that could globally transform the future of advanced manufacturing.

“Faculty support and exposure to the latest equipment and tools empowers our engineering students to work in new areas,” says David Flannery, a master’s student in materials science and engineering. “A lot of other universities are working with polymers, but we have the capabilities to work with metals, ceramics and composites.”

COLLEGE OF ENGINEERING DEGREES AT UNT

Jessica Reeder, an undergraduate student studying materials science and engineering, agreed.

“With all the new technology, it means a lot more capability for research and opportunities to be trained on different equipment,” she says. “We’ve had a lot of opportunities to work in research. When I talk to my family, everyone’s so excited when I tell them about the new machines and what they can do.”

Research conducted at the center will lead to smart materials and environmentally friendly technologies while helping Texas develop a highly skilled workforce of engineers.

“UNT faculty and student research have the opportunity to shape this emerging field — and that is part of what makes this so exciting,” says Dahotre, who is an internationally known expert in laser-based material processing that remains the basis of present additive manufacturing technology. In fact, Dahotre has been working on laser-based advanced materials manufacturing for the past three decades, even before the additive manufacturing term was coined.

UNT RESEARCHERS COLLABORATING TO MAKE NEW DISCOVERIES

Dahotre, in collaboration with three College of Engineering professors Rajarshi Banerjee, Rajiv Mishra and Andrey Voevodin, conceived the concept of UNT’s current Additive Manufacturing Lab, which will be integrated into CAAAM, and led the efforts to bring it into existence.

“I came to UNT to work in additive manufacturing and work directly with Dr. Mishra,” says Saket Thapliyal, a second year Ph.D. student who is originally from Northern India.

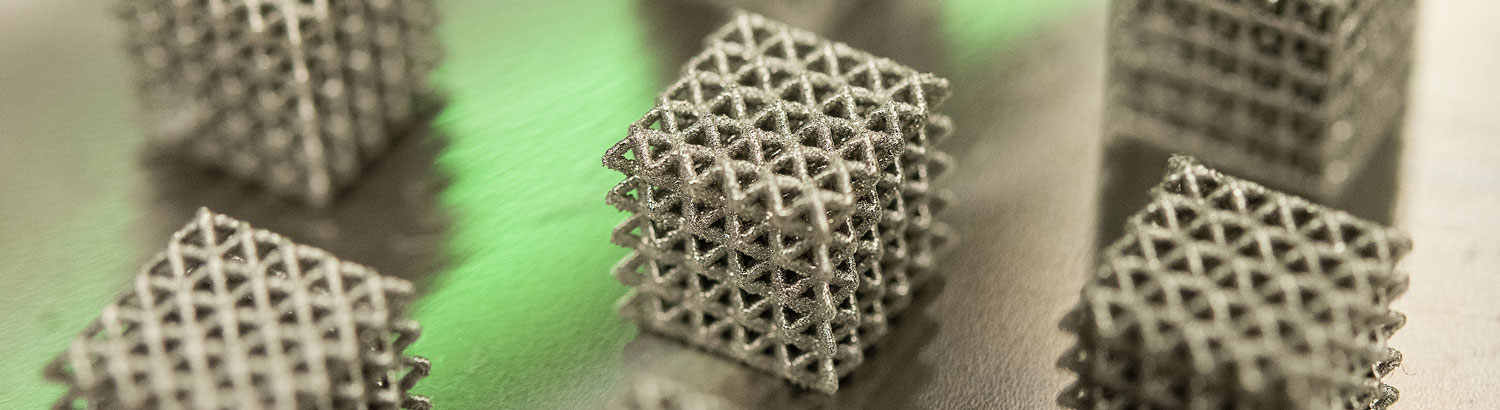

Researchers and students are using the equipment to create smart structures including medical implants.

“It can change the way we currently design our structures,” Thapliyal says. “As it will allow us to manufacture structures with smarter materials and shapes, just like nature. Nature is always multifunctional.”

Transforming Industry

Additive manufacturing may sound complicated, but the theory isn’t. Instead of building a sandcastle by subtracting sand away from a pile until the structure appears, imagine adding sand beginning at the bottom and moving up layer by layer until a castle is built. In the actual application of additive manufacturing, the grains of sand would be placed one at a time in a specific order pre-determined by an enhanced computer design.

Additive manufacturing is capable of producing higher-strength and more energy-efficient materials while reducing the actual amount of materials needed, wear and tear on parts and use of natural resources. The shapes created are anything but simple. These shapes can be hollow and contain other hollow, internal shapes like Russian nesting dolls. This allows for the printing of objects from struts to gears to be printed inside the primary shape as it is being created.

UNT OPENS 3D PRINTING LAB: ‘IT IS DEFINITELY A GAME CHANGER'

“Additive manufacturing is a new area of engineering,” says Banerjee, Regents Professor and director of UNT’s Materials Research Facility. “As such, there are many unexplored areas and unanswered questions. For example, we are finding that the structure of certain metallic materials has fundamentally changed after going through this process. The aluminum alloy powder used to create a component using additive manufacturing technology may look the same and be chemically similar to those produced using traditional manufacturing, but it has a different microscopic structure and properties. The question we are trying to answer is ‘Why?’”

At this time, most additive manufacturing involves plastics and polymers. UNT has taken the materials involved several steps further to include metals, ceramics and metal-ceramic composites. Due to the change that occurs to materials during processing, Banerjee’s research also involves the creation of additive manufacturing-specific alloys. These alloys are better adapted to additive manufacturing processes and provide for a consistent end product. Knowing how the process is affecting the materials is key to applying additive manufacturing in the manufacturing industry. The Material Research Facility houses characterization equipment that allows researchers to analyze the properties of 3D printed metal components and sets CAAAM apart from other additive manufacturing research facilities.

“For UNT, it’s not just about the research,” Banerjee says. “We provide a platform for education where students and faculty are exposed to the latest technology, and in turn we are providing a trained workforce for the future of manufacturing.”

NEW ADDITIVE MANUFACTURING LAB TO HELP RESEARCH AT UNT

The hands-on experience using the additive manufacturing and characterization equipment is providing students with new perspectives on the creation and development process, says Tyler Torgerson, a second year Ph.D. student who transferred from junior college to UNT and earned both his bachelor’s and master’s degrees here.

“We basically get to see and be a part of everything in the research process,” says Torgerson, who added that he came to UNT partly because of the university’s success in graduating and helping students get jobs at companies like Tesla and Intel. “Right now, I’m working on a project for the Air Force with additive manufacturing and nickel alloys using specific elements to better improve the properties. What are the effects on the alloys from the additive manufacturing? With the process you get very different properties from it. We’ll look at how the heat affects the materials. We are working to try to prevent some of the crashes and failures out in the field.”